Diverse Industry Solutions

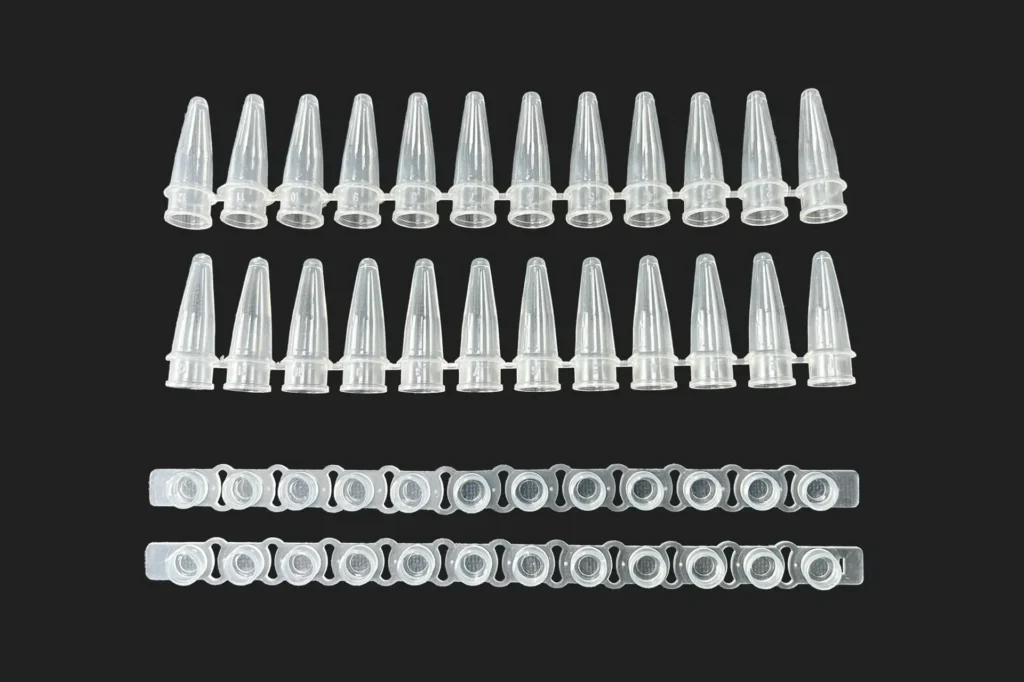

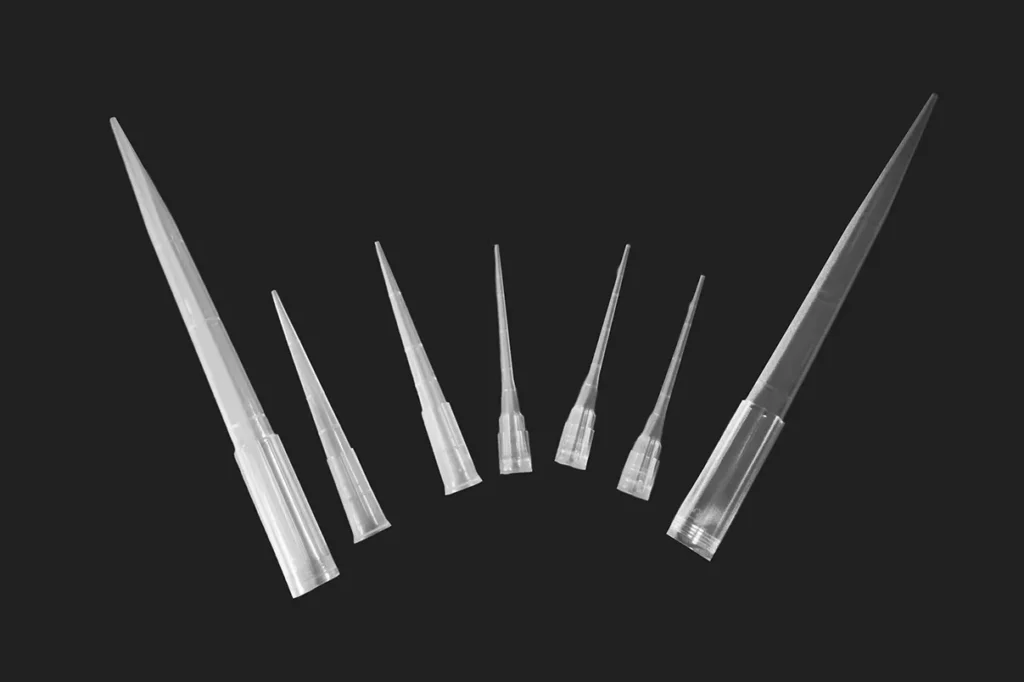

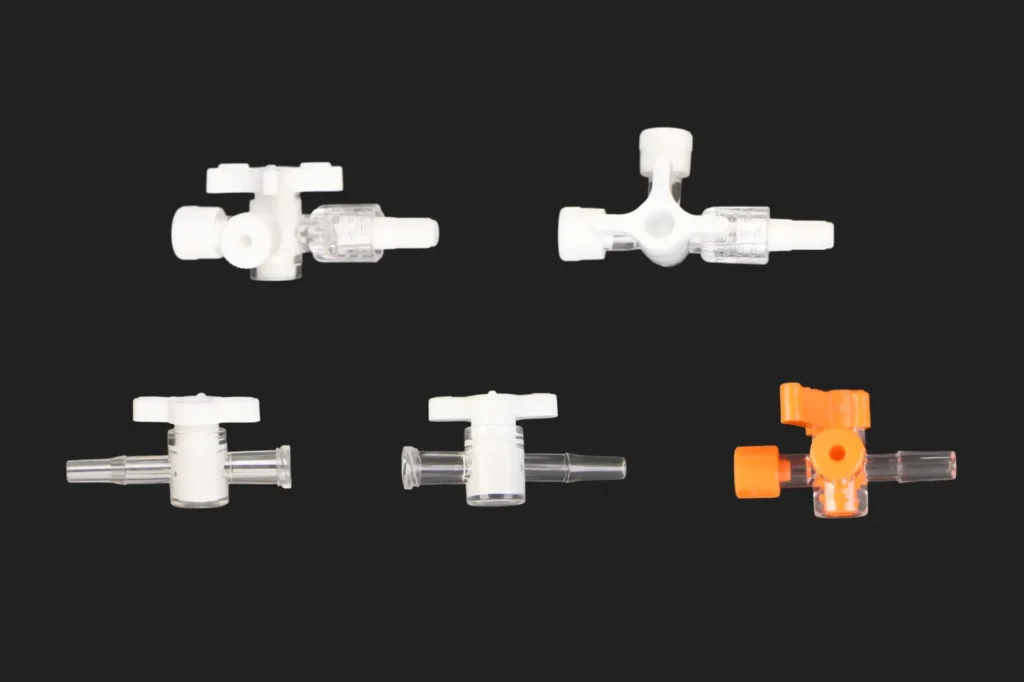

Medical molds

Belda-mold company equipped with a 100,000 class (ISO8 level) dust-free injection molding workshop, assists medical manufacturers with production. And, supports the injection molding production of PVC plastic molded medical products in a clean room environment, demonstrating its commitment to meeting the highest industry standards.

Automotive

Belda-mold company provides support for plastic injection tools used in the production of exterior automotive components. Additionally, Belda-mold offers assistance with low-pressure injection molding and in-mold graining nickel shell tools. The mold engineering and design team at Belda-mold is at the forefront of our industry.

Industrial molds

Quality is at the heart of what we do. For injection moulded parts, we implement a production part approval process (PPAP) for automotive applications and a CPK test for medical plastic parts production. All under the ISO9001 management.

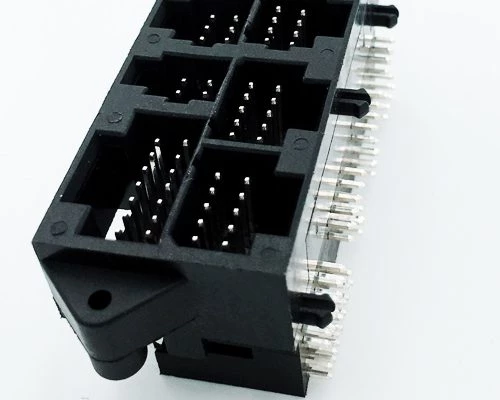

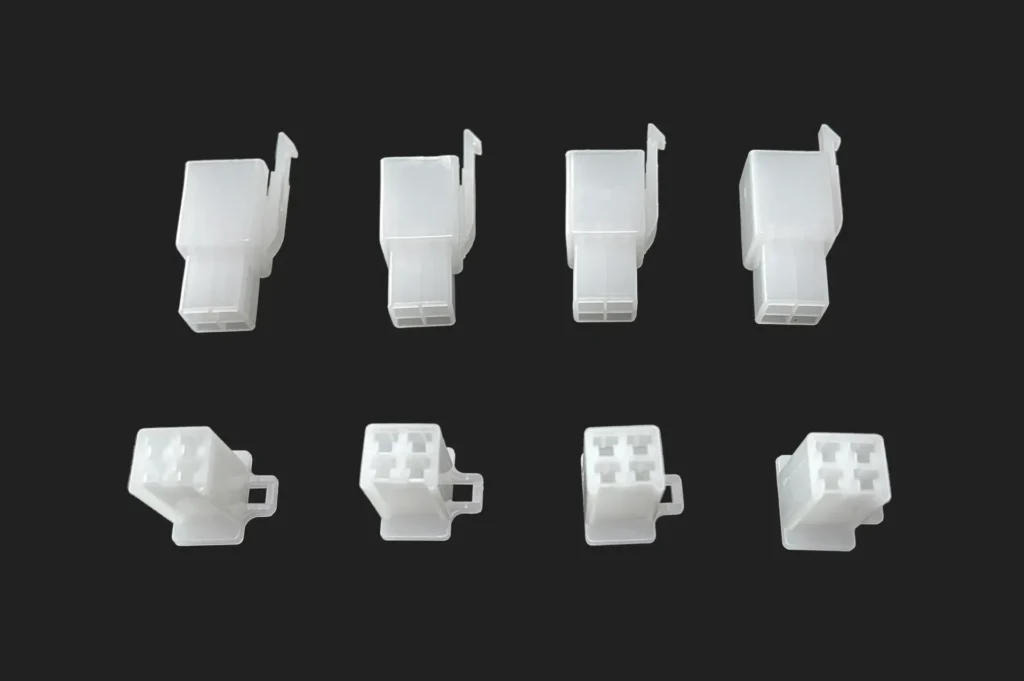

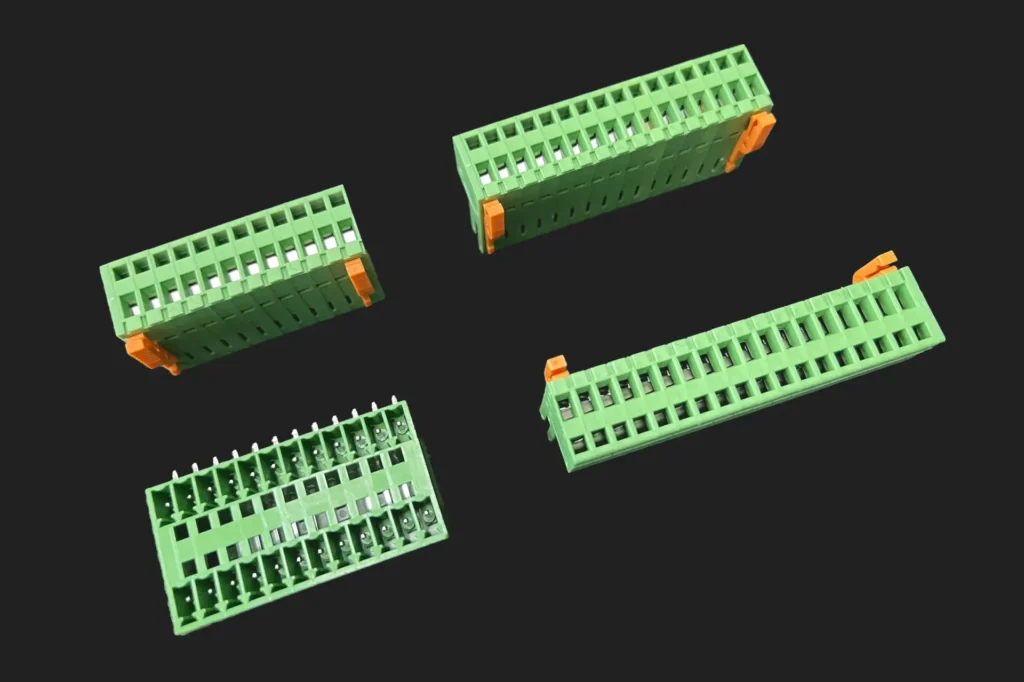

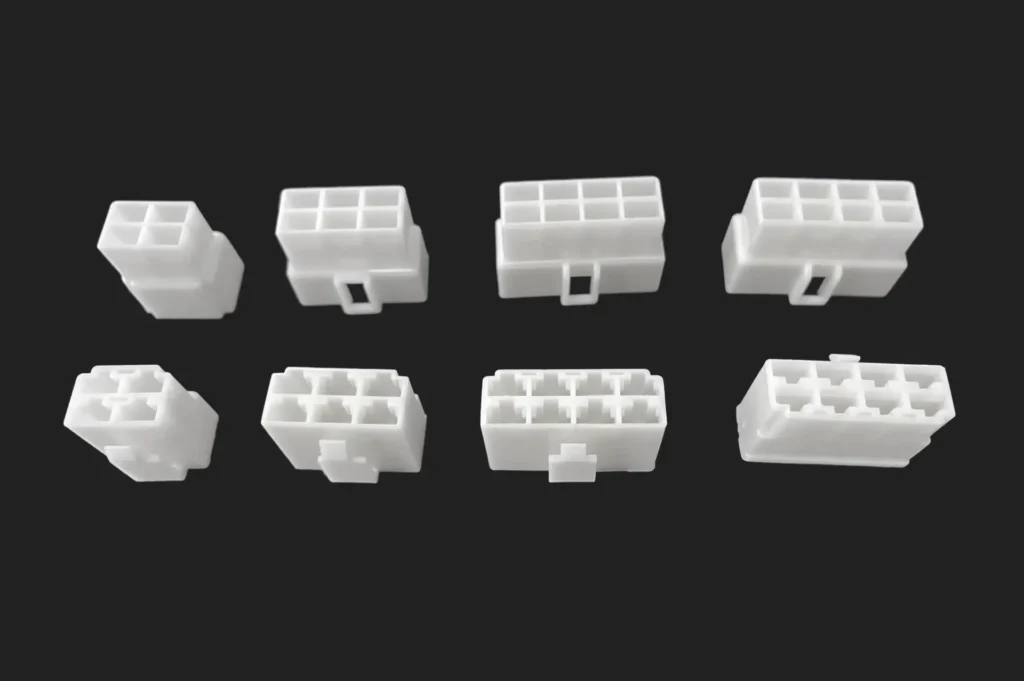

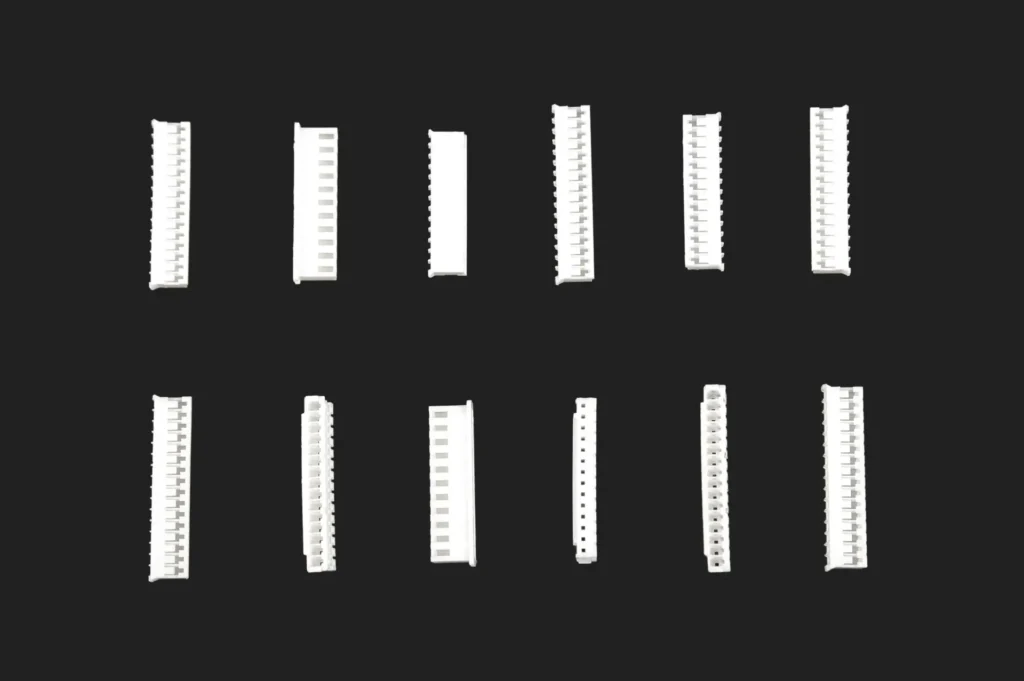

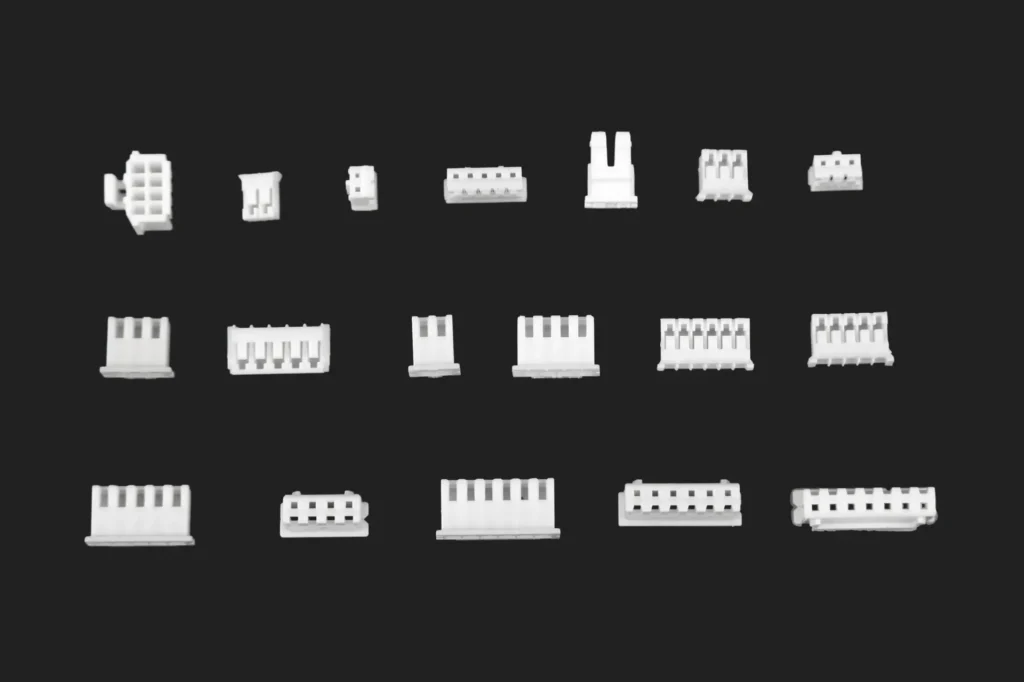

Electric & Electronics

What products have we made?

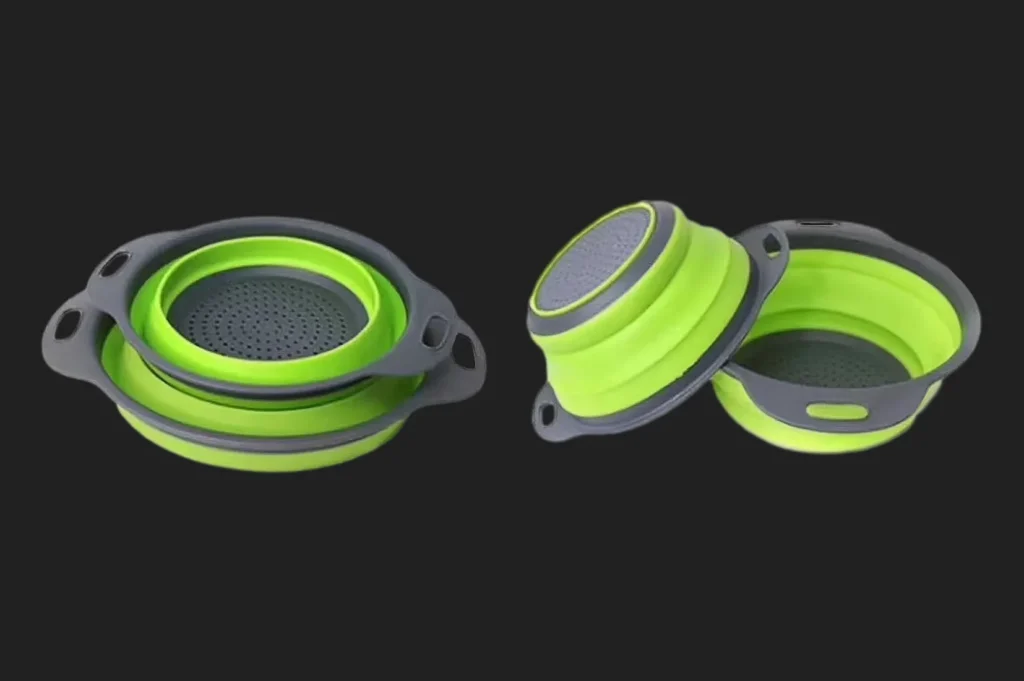

Auto Parts

Electronics

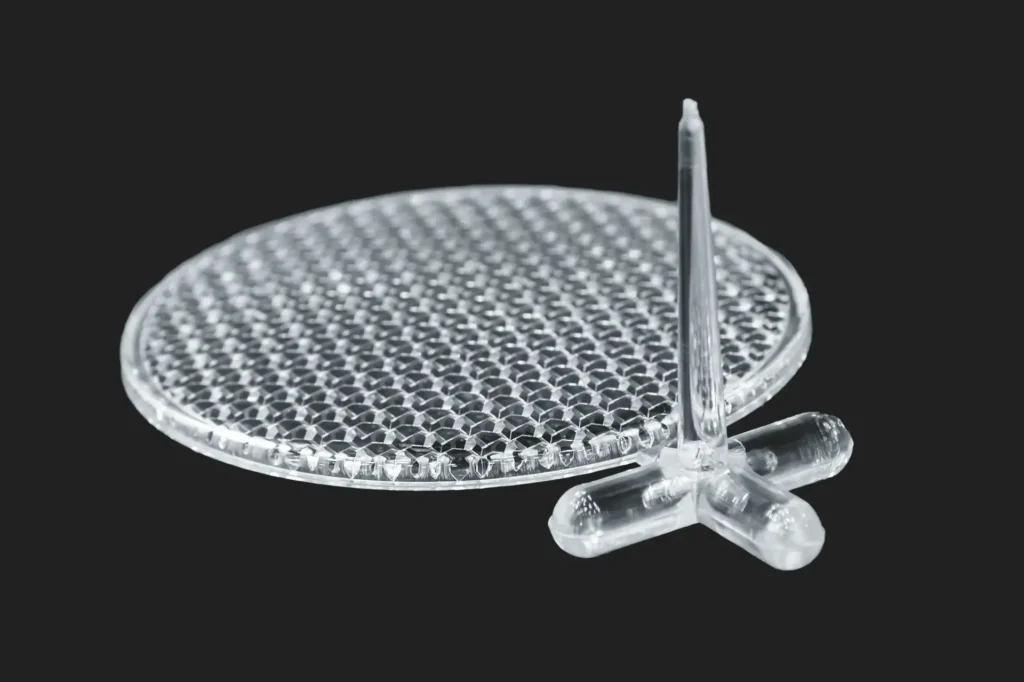

Medical

Connectors

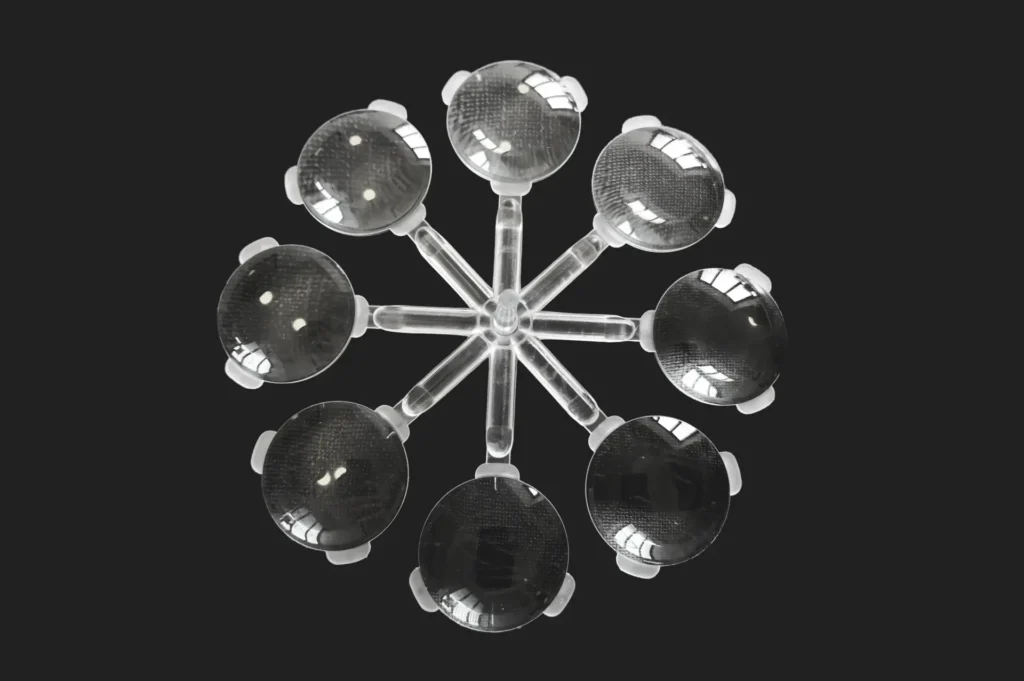

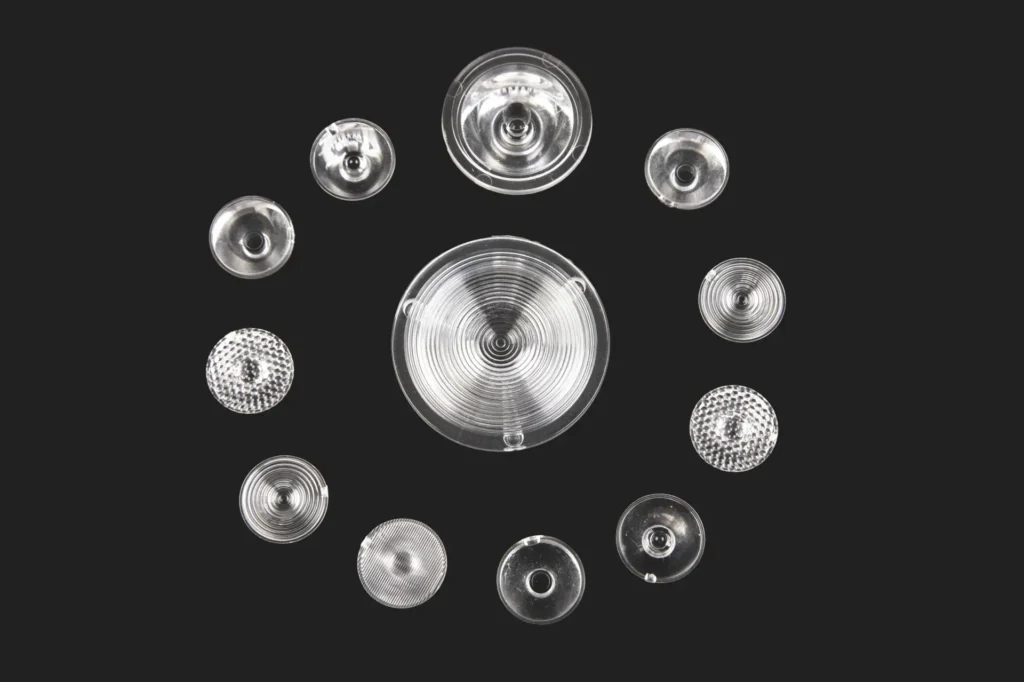

LED Parts

Two-Color & Multi-Color

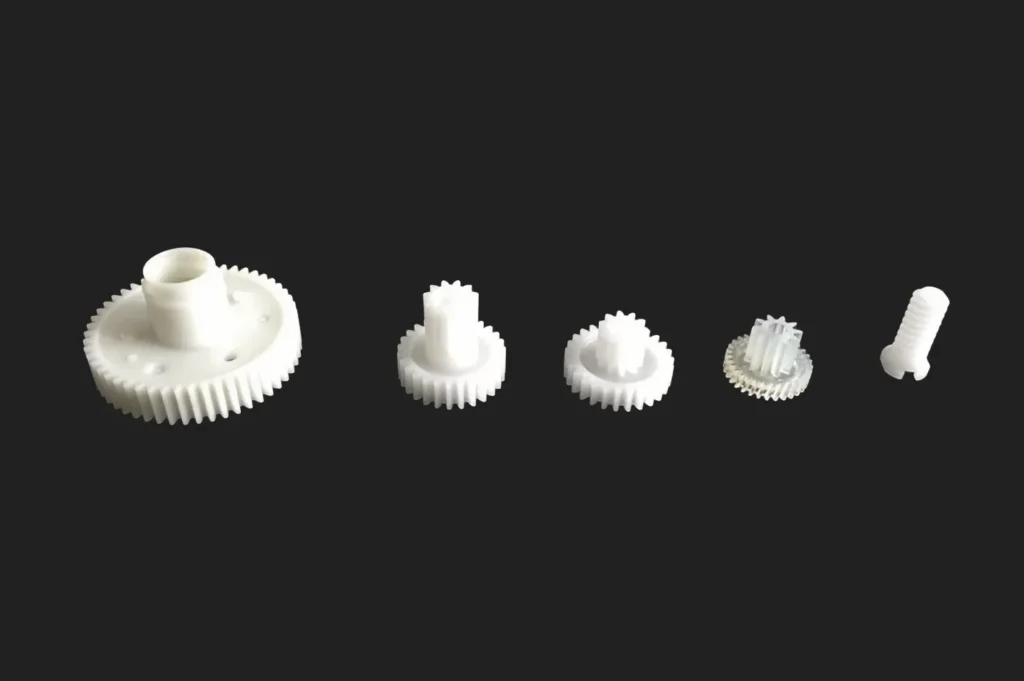

Gears

We can provide one-stop service

Product Design

Mold Design

Mold Manufacturing

Our comprehensive product design services ensure that we work with our clients from the beginning stages to make improvements on all technical drawings, including 2D and 3D files, to ensure the best possible outcome for each project.

Our expert team utilizes state-of-the-art technology and innovative strategies to deliver top-quality mold designs that are optimized for efficient and effective production.

Belda-mold company’s precision mold manufacturing process combines advanced technology with expert craftsmanship to deliver high-quality, durable molds for our clients

Injection Molding

Belda-mold’s injection molding process leverages cutting-edge equipment and techniques to produce top-quality plastic components for a wide range of industries

Surface Finishing

Belda-mold’s comprehensive secondary process services include surface finishing, assembly, and packaging to deliver finished products that meet our clients’ unique needs and specifications.

Our Equipment

CMM Inspection

High Speed CNC Machines

Double-Head EDM Machines

EDM Workshop

CNC machining Workshop

Plastic Injection Molding Room

Mirror EDM Machining

Mould Spotting Machine

Why choose Belda-mold?

Experience, Expertise, and Excellence: The Advantages of Choosing Belda-mold Engineering Solutions.

18+ Years Experience

Advanced Equipment

On-Time Delivery

For over 18 years, Belda-mold has excelled in creating plastic tools for the automotive, medical device, and electronics industries.

Belda-mold factory is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

Belda-mold schedules every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

One-Stop Solution

Good After-sales Service

Belda-mold mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

Belda-mold offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

Belda-mold is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Belda-mold Robust Capabilities Behind Numbers

2,000+

60+

14+

6.5M+

129+

Companies Served

Countries Shipped

Years in Business

Unique Parts Produced

Staffs