Capabilities

Offers product design, mold design, mold manufacturing, CNC machining, 3D printing, and more, our company delivers comprehensive capabilities for precision molds that drive efficient production processes.

Product Design

Product design is an essential step in creating a successful product that meets both manufacturer goals and end-user needs. It involves balancing technical, economic, and aesthetic requirements with specific user requirements. Experienced product design team collaborates intimately with clients to define and optimize design specifications, balancing technical, economic, and aesthetic aspects to meet end-user needs.

Product Design Process

1. Define Product

2. Define Product

3. DFM Report

4. Mold 2D/3D Design

5. Customer Approve of Mould Design

6. Mould Production

7. Mould Trial

8. Sample Inspection

9. Customer Approve of Sample

10. Mould Delivery

Mold Design

Mould Design Process

1. Project Plan

2. DFM Report

3. Mold 2D/3D Design

4. Customer Approve of Mould Design

Mold Manufacturing

Mold Manufacturing Process

1. Project Plan

2. DFM Report

3. Mold 2D/3D Design

4. Customer Approve of Mould Design

5. Mould Production

6. Mould Trial

7. Sample Inspection

8. Customer Approve of Sample

9. Mould Delivery

Plastic Injection

Belda-mold offers cost-effective, high-volume plastic injection molding, creating high-quality parts for diverse industries, with specialized services like ISO8 cleanroom production for the medical sector. From the automotive components that ensure our safety on the road to the medical devices that save lives, precision plastic injection mold design is a craft that requires experience, expertise, and a relentless commitment to excellence. Always know that behind that precision is an expert mold designer, diligently working to ensure that every detail is just right.

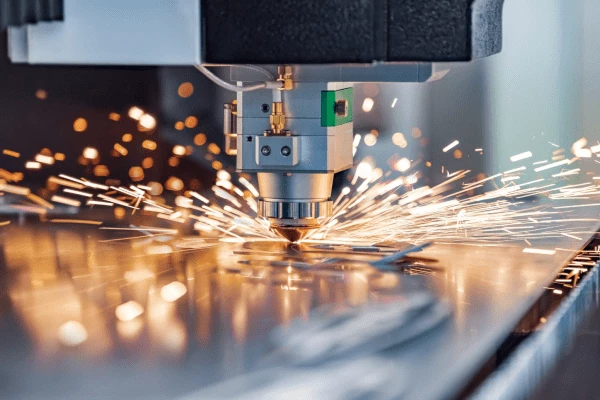

CNC Machining

CNC Machining Process

1. Design Input

2. CNC Milling and Turning

3. Precision Machining

4. Quality Control and Delivery

Rapid prototyping

Explore the Versatility of Rapid Prototyping: Dive into the diverse world of rapid prototyping, where advanced methods like CNC Machining, 3D Printing, Vacuum Casting, and Silicone Overmolding bring your innovative designs to life swiftly and accurately.

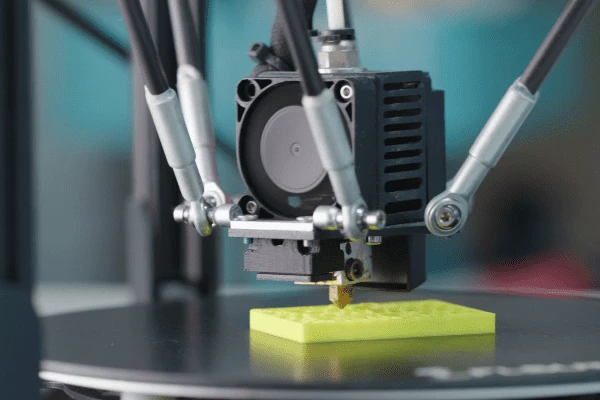

3D Printing

Belda-mold offers 3D printing services to clients in areas such as plastic mold creation, industrial design, robotics and automation. Over time, it’s also been used for direct product manufacturing. The technology is applied in various fields, including jewelry, footwear, industrial design, architecture, automotive, aerospace, medical and dental sectors, education, geographic information systems, civil engineering, firearms, and more.

3D Printing Process

1. Design Preparation

2. Slicing

3. 3D Printing

4. Post-Processing

Surface Finishing

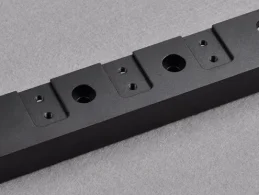

CNC machining metals

Bead Blasted + Anodized Type II (Glossy)

Electroless Nickel Plating

Black Oxide

Powder Coated

Bead Blasted

Brushed (Ra 1.2μm / Ra 47μin)

Injection molding plastics

Textured

Matte

Semi-Glossy

Glossy

Sheet metal fabrication